Air Density Impacts on Fan Performance Part Two: The Effect on Performance

Previously, in part one of this series, we determined how changes in humidity, temperature, and altitude can affect air density. We will conclude this two-part series by discussing the effects on fan performance caused by changes in air density.

Effects on Performance

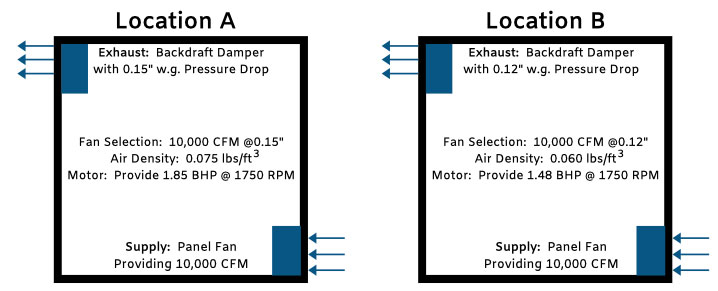

Let’s create a very simple ventilation system to use in locations with varying air density and compare the outcomes. The customer building is approximately 60,000 cubic feet and would require 6 air changes per hour. The ventilation system will consist of one panel fan for mechanical supply and one backdraft damper for natural exhaust.

For our simple ventilation system in Location A, we make our fan selection based on Standard Air conditions that have an air density of 0.075 lbs/ft3 and based on air flow and static pressure requirements we will need a motor to provide 1.85 BHP @ 1750 RPM.

Now assume that we move our simple ventilation system to Location B where the air density is only 0.060 lbs/ft3. How much air flow does the fan provide in the new location? The answer is that it provides exactly same air flow of 10,000 CFM. Fans are constant volume machines and will move the same volume of air regardless of the air density.

However, in Location B, our system pressure and horsepower will change in proportion to the change in air density ratio. The air density ratio is equal to 0.80 (0.060/0.075) so our new system pressure is 0.80 x 0.15 = 0.12” w.g. and the required horsepower is .80 x 1.85 = 1.48 BHP. Since the air weighs less in Location B, the fan requires less horsepower to move the same volume of air.

I’m going to make the scenario more complicated. The requirement now is that the building where we have our simple ventilation system needs to have positive pressure of 0.15” w.g to keep out air infiltration. In Location A, our fan selection is now based on a total system static pressure of 0.30” w.g. and 10,000 CFM. If we keep the motor speed the same, the required horsepower is 2.02 BHP. If we move this new system to Location B, it will have a total system pressure of 0.80 x 0.30 = 0.24”w.g. and the required horsepower would be .80 x 2.02 = 1.62 BHP.

The problem we have now in Location B is that we only have a fan capable of producing a 0.12” w.g. positive pressure (0.80 x 0.15 = 0.12) when we needed 0.15” w.g. What we need for Location B is a fan that can provide 10,000 CFM at a total system pressure of 0.27” w.g. based on .060 lbs/ft3 air density. To get that, we need to adjust the positive pressure requirement of 0.15 in w.g. by the inverse of the air density ratio. So now the Location B fan selection is made with Standard Air conditions of 0.3375” w.g. total system pressure and 10,000 CFM. When in operation, our simple ventilation system in Location B will have system pressure of 0.27” w.g., provide 10,000 CFM, and require 1.66 BHP @ 1750 RPM.

In Summary

- The three factors that determine ASHRAE Standard Air Density of 0.075 lbs/ft3:

- 70ºF temperature

- Sea Level altitude

- 0% relative humidity

- Altitude has the greatest impact on air density.

- Fan air flow is the same regardless of air density.

- When air density is different from Standard Air density, system pressure and fan motor BHP change in proportion to the air density ratio.

Conclusion

I will end this two-part series with a pro-tip:

When using fan selection software and you are limited to Standard Air Conditions you can calculate the static pressure and motor BHP of Location B by using the inverse of the air density ratio multiplied by Location B’s total system static pressure.

We appreciate you following along and hope that you have taken away valuable knowledge of air density impacts on fan performance.