Ventilation Systems for Hazardous Areas Part 1: The Codes

Our customers often ask us to design a ventilation system for a hazardous area where there is a fire or explosion potential due to flammable gases, vapors or dust. Designing the right ventilation system for a customer’s particular application requires:

- Understanding what codes apply;

- The amount of air flow required to eliminate the hazard;

- Where the equipment should be positioned; and

- How the equipment should be manufactured.

In the first of this three part series, I will discuss the codes that apply to how we design an explosion proof ventilation system.

The Codes

There are three primary codes to follow for a ventilation system for a hazardous area:

- National Fire Protection Association (NFPA) Standard 91, Exhaust Systems for Air Conveying of Vapors, Gases, Mists, and Noncombustible Particulate Solids;

- National Electric Code (NFPA 70); and

- Air Movement and Control Association (AMCA) Standard 99-16.

Here is a brief description of each:

NFPA Standard 91 is the overall guideline for how ventilations systems for hazardous areas should be designed, equipped, tested and maintained. Because the danger with ventilation equipment in a hazardous area is the risk of a spark from electrical or mechanical components, NFPA 91 incorporates standards from the NEC/NFPA 70 for electrical components AMCA 91 for mechanical components.

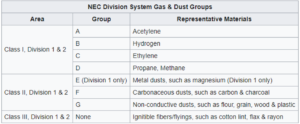

NEC/NFPA 70 is the standard for determining the type of hazardous area. It uses a system of classes, divisions and groups to define which hazardous material may be present and the concentration level. This table summarizes the NEC system:

AMCA 99-16 is the guideline to be used by the manufacturer and end user for establishing general methods of spark-resistant construction. The standard applies to centrifugal, mixed flow, axial and propeller fans, power roof ventilators and dampers.

In part two of this series, I’ll discuss the importance of the amount of airflow required and the location of the equipment in designing an explosion proof ventilation system.