What You Need to Know about Heat Stress

Heat stress is a very real concern in hot weather. Not only can it have a detrimental effect on machinery but of a more major concern, it can be very hazardous and even fatal to people exposed to hot work areas. Luckily, there are precautions you can take to prevent heat stress.

THE EFFECT OF EXTREME HEAT ON THE BODY

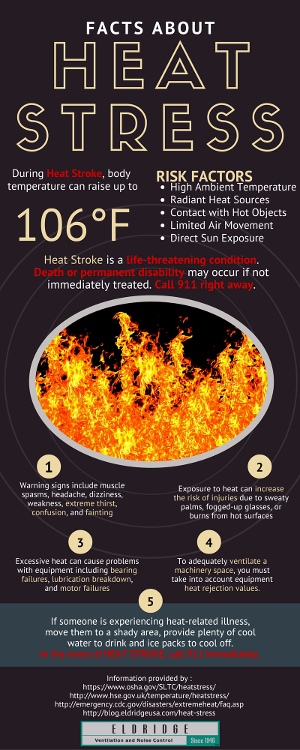

As OSHA explains, heat becomes a hazard for workers when the ambient temperature reaches close to body temperature. This makes it difficult for the body to regulate its own temperature. As the ambient temperature rises, it becomes increasingly difficult for the body to cool itself through the normal process of perspiring. When this happens, heat gets retained within the body, which can lead to impaired cognition, fainting, or even death.

It’s important to keep in mind that it’s not just ambient temperatures that can be a problem; if someone is working in close proximity to high heat-producing equipment, they can become overcome by heat in a short amount of time. Keeping the areas that house heat-producing equipment properly ventilated can alleviate this problem.

THE EFFECT OF EXTREME HEAT ON EQUIPMENT

Heat can also be a problem for machinery and equipment. For example, electric motors, electric switchgear, air compressors, and recip-engines all have temperature limits for effective and long-lasting operation. Since all this equipment gives off heat, it is not a satisfactory operating condition to simply have the generated heat remain in the associated machinery space. The machinery space just gets hotter and hotter and the life span of the equipment gets shortened. You run the risk of mechanical problems, bearing failure, lubrication breakdown, internal circulated liquid cooling loss, inadvertent shutdowns, and motor or electric gear failures.

Heat can also be a problem for machinery and equipment. For example, electric motors, electric switchgear, air compressors, and recip-engines all have temperature limits for effective and long-lasting operation. Since all this equipment gives off heat, it is not a satisfactory operating condition to simply have the generated heat remain in the associated machinery space. The machinery space just gets hotter and hotter and the life span of the equipment gets shortened. You run the risk of mechanical problems, bearing failure, lubrication breakdown, internal circulated liquid cooling loss, inadvertent shutdowns, and motor or electric gear failures.

PRECAUTIONS YOU CAN TAKE

WORKER SAFETY

Carrying out a risk assessment for your location can be beneficial to determine the best course of action for your environment and staff. You should encourage workers to stay hydrated and to take regular breaks to prevent themselves from overheating. If possible, allowing workers to wear lighter clothing can also reduce heat-related issues.

Having a Heat Stress Management Plan is also a good idea. Take a look at this example from OSHA’s website. A Heat Stress Management Plan will designate official resting areas and cooling stations as well as provide guidelines for workers with regard to acclimatization and personal protection equipment. The Plan will also designate roles to individuals who will take on different responsibilities in the event of an emergency. In an emergency, it is imperative to have trained staff with the knowledge of what to do, as others in the vicinity may panic under stress.

EQUIPMENT MAINTENANCE

For workers in the engine room where engine surface temperatures can reach upwards of 400°F, the radiated and convected heat will make the space feel like an oven. By having the proper air change rate within the space and by keeping cooler outside ambient air moving, workers will be better equipped to handle the heat.

We highly recommend installing a properly engineered and designed ventilation system and equipment to keep air moving through machinery spaces where high heat sources exist. You may read that certain areas require a certain number of air changes per hour to be considered adequately ventilated. In our experience, these air changes are not enough because they don’t consider the heat let off by equipment.

It has been our practice to base the amount of ventilation required on the amount of air required to cool the area to an acceptable level based on heat rejection values as opposed to simple rates of air change. For example, some industry guidelines may indicate that an air change rate of 30 times per hour (1 air change every 2 minutes) is satisfactory for an engine room; however, when the heat rejection rate of the engine(s) is taken into consideration, the air change rate of 30 times per hour is totally inadequate and actually yields internal space temperatures in excess of 40°F to 50°F degrees above outside ambient conditions. This is one of the many reasons it’s so important to hire a ventilation specialist to ventilate these potentially high-risk areas.

Eldridge is available year-round to conduct Heat Load Evaluations of land-based facilities and also offshore installations. For offshore, our staff is BOSIET certified (including HUET, EBS, Safe Gulf / Safe Land) and ready for worldwide deployment. Contact us today to speak to a ventilation professional.