Ventilation Systems for Hazardous Areas Part 3: Manufacturing Equipment

In Parts 1 and 2 of this series, we discussed The Codes that apply and the Two Key Factors that go into the design of an explosion proof or hazardous area ventilation system. In this third and final part, we will discuss how ventilation equipment should be manufactured to reduce the risk of sparks that may cause an explosion.

Explosion Proof Fans

At the heart of most explosion proof or hazardous area ventilation systems is an explosion proof fan. To be considered explosion proof, a fan needs to be able to prevent either an electrical or mechanical spark. The electrical components of a fan that may cause a spark are the junction box and motor. To keep the junction box out of the hazardous air stream, the motor is manufactured with extended leads so the junction box can be located on the outside of the fan.

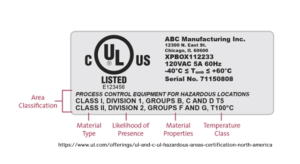

The explosion proof construction of an electric motor is based on the class, division and group of the potentially explosive material present in the air stream (See Part 1: The Codes). As a fan manufacturer, we rely on the third party certification that a motor meets the criteria for the appropriate class, division and group standard.

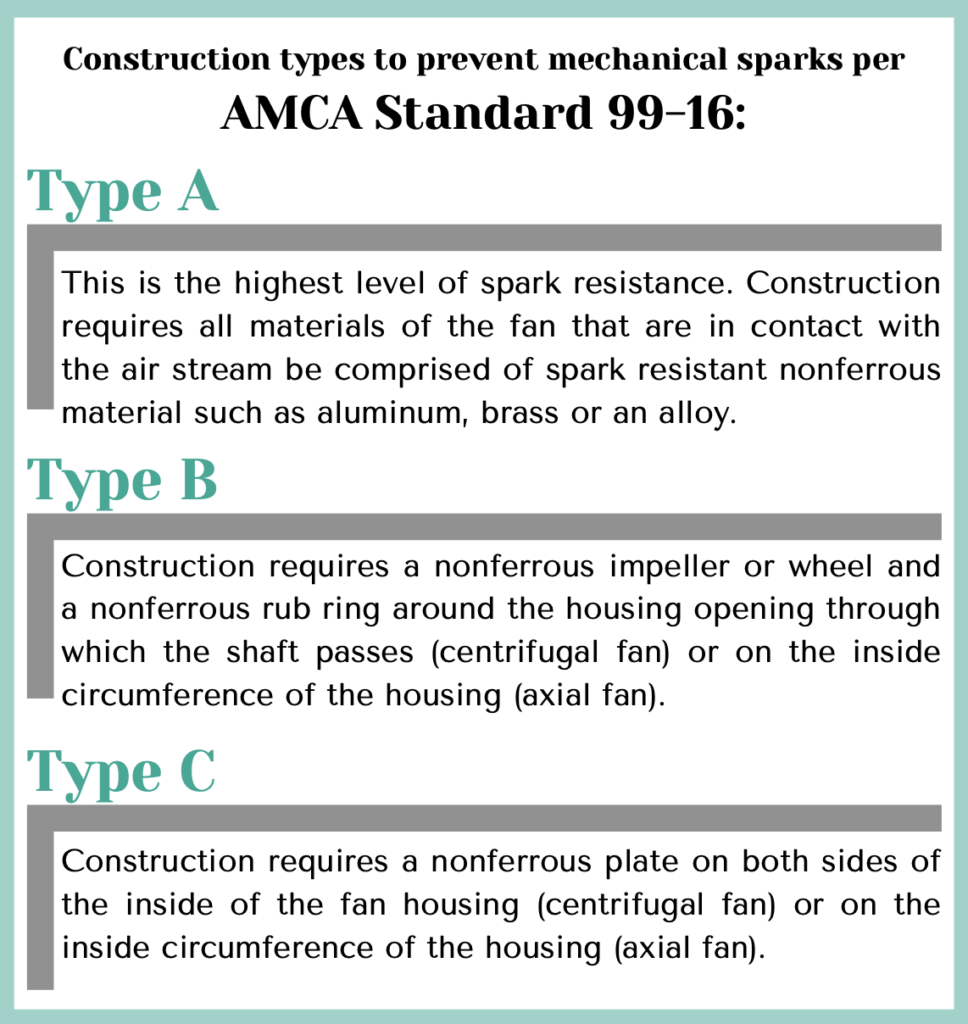

The type of spark resistant construction used for the fan depends on the potential risk of two metal pieces coming in contact. All three construction types will provide spark protection in the event of the impeller or wheel contacting the housing. However, if there is a risk for a ferrous metal part entering the fan from some other source upstream, only Type A construction will provide protection.

Other Explosion Proof Ventilation Equipment

An explosion proof or hazardous area ventilation system may require other components that will also need to be explosion proof. We have designed systems that also required dampers, heaters and desiccant dehumidifiers. All of these components can also be manufactured to be explosion proof by following codes to prevent the risk of sparks and autoignition.

Conclusion

We hope that you have enjoyed understanding a little bit more of what goes into analyzing, designing and manufacturing an explosion proof or hazardous area ventilation system. Not having the right ventilation system for your hazardous area creates a serious safety risk for your employees. At Eldridge we have over 70 years of experience with these types of systems and have taken on the challenge for unique applications when no one would. When you need a new or redesign hazardous area ventilation system, let us help you create a safe and successful environment for your employees.